Dura-Line’s Clinton plant achieves ISRS Certification

Clinton Plant Manager Lisa Jenkins said, “We were the first plant to be audited and to be certified. We’re proud to be leading the way.”

Representing more than 35 years of accumulated best practice experience in safety and sustainability management, the ISRS certification procedure reviews the entire management system including risk management, environmental aspects, the health and wellness of employees, and an overall assessment of management as a whole process.

According to DNV-GL’s website, “ISRS is a world-leading system used to assess, improve and demonstrate the health of an organization’s business processes. Using ISRS gives organizations and their stakeholders’ peace of mind that their operations are safe and sustainable.”

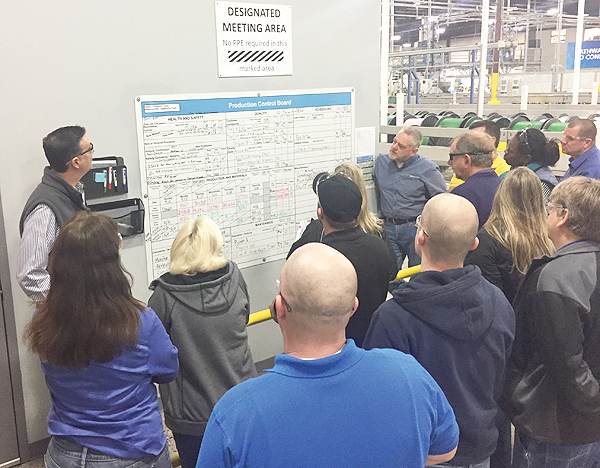

“It is not the safety systems alone that achieve success in certification,” said Matthew Caruso, Environmental Health and Safety Manger U.S./Canada. “It is how the site manages the business and involves and engages employees at all levels that brings success.”

Billy Heatherly, Safety Coordinator at the Clinton Plant, said, “I think the certification is great because it shows all the hard work the management team has put in and to get it on our first try is a big accomplishment for everybody. It shows how well this management team works together and how seriously we take our jobs.

“But, really it takes a total buy-in from everybody at the plant. The auditors look at everything with a microscope. If everyone wasn’t doing their part, it would have shown in the audit for sure.”

Early in 2013, Mexichem embarked on a safety initiative through DNV-GL called ISRS. Early in 2017, U.S. and Canada Dura-Line sites began working on establishing the foundation for ISRS Certification. ISRS Edition 7 was chosen since it is the most applicable edition to general industry while including the evaluation of not only safety