Help wanted: Building the skilled trades pipeline for jobs

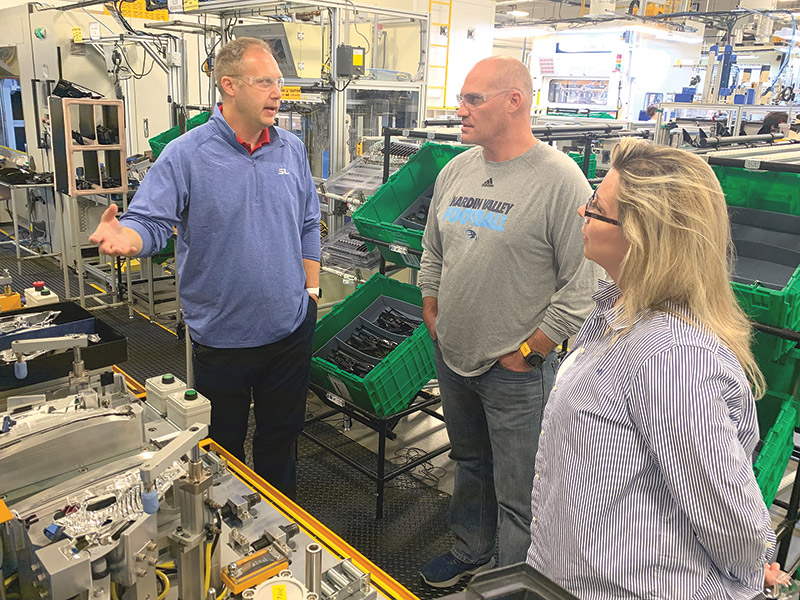

Scott Laska, operations manager at auto parts manufacturer SL Tennessee, shows a fully assembled lamp to Knox County STEM teachers. SL Tennessee’s lamps are placed on vehicles at a General Motors plant within 72 hours after assembly.

“Manufacturing jobs are out there locally, but they require training,” said Furman, who teaches physics and chemistry. “Seek out areas you would like to work in and then find a training program that will get you there.”

Furman, along with 23 other teachers from 10 Knox County schools, recently toured auto parts manufacturer SL Tennessee in Anderson County and participated in a panel discussion with business, industry, and technical college leaders.

The educators learned more about science, technology, engineering, and math, or STEM, careers in manufacturing, and the growing need for a reliable, skilled workforce in the region. Knox County Schools, SL Tennessee, and the Y-12 National Security Complex jointly sponsored the professional development opportunity.

Jobs in our own backyard

“The takeaway from the day for me was, how can I get students to see the wonderful opportunities that are available to them in their own backyard?” said Furman, who has also toured Denso and other area manufacturing facilities. “My role as a STEM teacher is to help students become aware of opportunities beyond the classroom and post-secondary. I try to tie in curriculum to where it is found in the real world.”

Lori Musico, science department chair at Karns Middle School, said she was pleased to discover local industry job openings that provide on-the-job training and advancement opportunities.

“I want my non-college-bound students to understand that their education and proficiency in math and science translates into skills needed by area manufacturing employers,” Musico said. “Employment in manufacturing is a viable option for students, especially given the excellent starting pay and benefits and opportunities for continuing education and career growth.”

Statewide technical training offered

Local industry and students alike often tap into statewide technical training and certificate programs offered by area community colleges and Tennessee College of Applied Technology, with several campuses in the region.

SL Tennessee Operations Manager Scott Laska shared with the STEM teachers that his company, which assembles head and tail lamps and gearshift mechanisms, often supplements in-house training with mechanics, automation, robotics, electronics, pneumatics, hydraulics, and other classes offered by Roane State Community College.

“We work through Roane State a lot for mechatronics training,” Laska said. “Come in with a positive attitude and a willingness to learn, and we’ll teach you what you need to know. We’re growing our labor pool of qualified employees to ensure our future growth in STEM areas.”

Filling the pipeline with a trained workforce

Panelist Kim Harris, Roane State’s director of Workforce Training and Placement Services, emphasized that securing a good manufacturing job often involves students, parents, educators, industry, and technical schools and programs all working together.

“Try summer externship opportunities in manufacturing,” Harris recommended to teachers. “Expose your students to this employment sector. Employers are eager to help recruit students as their future workforce. Let them know what is needed and how they can help. Don’t assume they are too busy to get plugged in. Many companies have foundations that could provide grant funds for various projects if they align with the company’s mission.

“We all must work to be more proactive in filling the pipeline with a trained workforce,” Harris said. “Even with automation and robotics, a trained workforce is crucial to the success and competitive edge of America’s manufacturers.”

Skilled trades needed for

national security applications

The Y-12 National Security Complex sponsored the teacher in-service as part of its educational outreach efforts to develop the STEM proficiencies the site needs to fill skilled trades jobs.

“For more than 75 years, Y-12 has been successful because of the exceptional talent and tremendous contributions of its employees,” said Kristin Waldschlager, Y-12’s educational-outreach coordinator. “With more than 5,000 employees, today’s Y-12 workforce has a median age of 49. In 2025, 43% of today’s Y 12 workforce will be retirement eligible.”

In addition to Laska and Harris, other panelists included Rick Meredith, president of the Anderson County Chamber of Commerce; Danni Varlan, member of the Tennessee Board of Regents; and Anita Hazlewood, a Y-12 chemical engineer. Y-12’s Gene Patterson moderated the panel session.

Consolidated Nuclear Security, LLC, operates the Pantex Plant in Amarillo, Texas, and the Y-12 National Security Complex in Oak Ridge under a single contract for the U.S. National Nuclear Security Administration.

Pantex and Y-12 are key facilities in the U.S. Nuclear Security Enterprise, and CNS performs its work with a focus on the absolute priorities of safety, security, quality, mission delivery and cost efficiency.